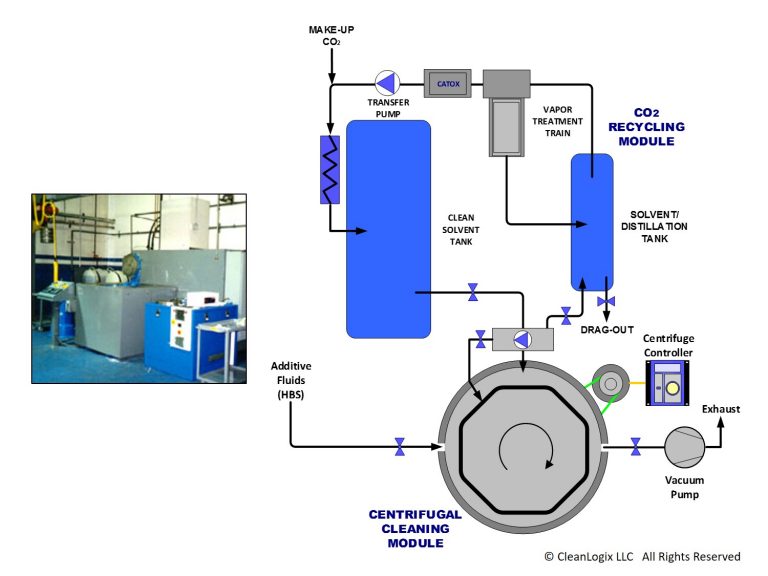

Centrifugal CO2™ immersion technology combines the solvent power of liquefied or supercritical carbon dioxide with patented bi-directional centrifugal cleaning action to effectively remove contaminants from the complex surfaces, both internal and external, of a product. Shown in the figure above, a centrifugal liquid CO2 system comprises two modules: a centrifugal cleaning module and the CO2 recycling module. The principle of operation is similar to a closed vapor degreasing system.

Products to be cleaned are placed into the cleaning chamber and the lid is closed and sealed. The operator presses the start button on a graphical display console and clean liquid CO2 is automatically transferred from a supply vessel within the recycling system into the centrifugal cleaning chamber. During and following the fill cycle, the centrifugal liquid CO2 system cleans the products using bi-directional centrifugal agitation for a pre-determined cleaning cycle time. Following the centrifugal wash (or rinse) cycle, contaminant-laden liquid CO2 is transferred from the centrifugal cleaning system into the recycling system for phase separation and recovery operations. Clean, dry products are removed from the chamber and the cleaning process is complete. In the background, the recycling system separates contamination (or additives) from the liquid CO2 and is removed as a drag-out. The drag-out is captured and filtered for re-use or disposal and the recovered (purified) CO2 is transferred into the supply tank for reuse. The recycling module is capable of economically recovering 90%-95% of the CO2 for reuse. Moreover, the recycling module can operate in an off-line (batch mode) or in-line (continuous mode).

CO2 is a solvent much like fluorinated solvents. As such, it will remove many but not all types of surface contaminants. Examples of contaminants which are soluble in liquid CO2 include hydrocarbon oils and silicone oils. Contaminants that are not particularly soluble in liquid CO2 alone can be solubilized by employing proprietary high boiling additives in the process.

The centrifugal liquid CO2 immersion cleaning process can meet a variety of cleanliness requirements, ranging from visually clean to more rigorous quality standards requiring sophisticated test methods such as ASTM E595 TML and VCM, Non Volatile Residue (NVR) analysis, FTIR, or Scanning Electron Microscopy (SEM).

Factory-Tool-Line Adapted Solutions

Clean Imagineering is a developer and value added reseller of lean and green (clean) manufacturing solutions utilizing unique combinations of state-of-the-art CO2 based cleaning, oxygenated machining fluid, non-contact inspection, robotic automation, and 3D printing technologies. We bridge the technology, knowledge, creativity, and implementation gaps between the clean manufacturing technology suppliers and the end-user (you)! Our applications engineers and OEMs work with your team to develop and implement clean manufacturing solutions tailored to your specific needs. We provide turn-key process development and customized equipment designs – including 3D design and printing, robotic automation and implementation, lab testing, contract cleaning, and short-term equipment rental services for on-site process development.